Preparing classic trousers for fitting #F03

In the following step-by-step instructions, I will explain how I prepare trousers for fitting if they have a divided waistband. I also explain the preparation for optional hem turn-up here. If you have opted for trousers without a divided waistband and turn-ups, you can use these instructions to prepare the trousers for fitting.

We strongly recommend fitting made-to-measure trousers before finishing them. If you have garments tailored professionally, customers always go in for a final fitting before the garment is finished. That’s why our patterns also include wider seam allowances, which you can use to adjust if necessary. It is important that the waistband is sewn on when trying on the trousers for fitting. Especially when choosing the shaped waistband, because the circumference at the bottom edge is much larger than at the top edge. Since the trousers will be taken apart again after fitting, I will sew the pieces together with a long machine stitch and barely secure them. However, you can also baste the seams by hand, which is particularly recommended for delicate fabrics. Enjoy preparing your trousers for fitting!

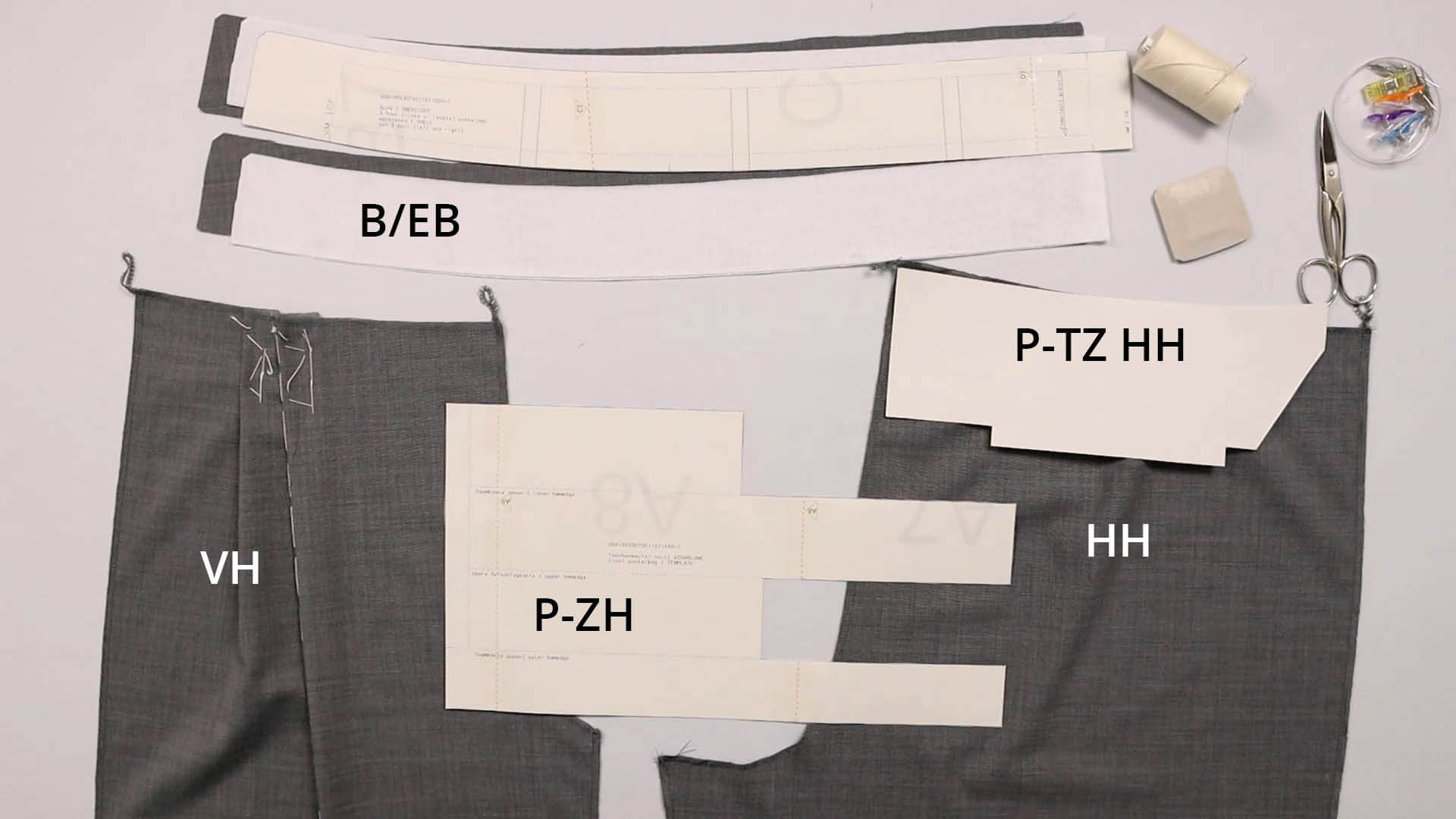

1. This is required

Pattern pieces made from main fabric:

- back trousers (HH) – 1 pair; the darts are already incorporated

- Front trousers (VH)- 1 pair; the area for the side pocket (wing pocket) is still attached fitting.

- 2 pairs of waistbands (B); these will later have a seam at the center back

Pattern pieces from interfacing:

- waistband (EB) – 2 pairs

Paper pattern pieces:

- back (HH)

- front (VH)

- waistband (B)

- if necessary, the template for the back pocket position (P-TZ HH)

- if necessary, the template for the turn-up hem (P-ZH)

Tools and aids:

- pins or clips

- scissors

- chalk or fabric marker

- basting thread and hand sewing needle if necessary

2. Prepare the waistband

Here I am anticipating the instructions for the waistband processing. This will save you a few work steps later on.

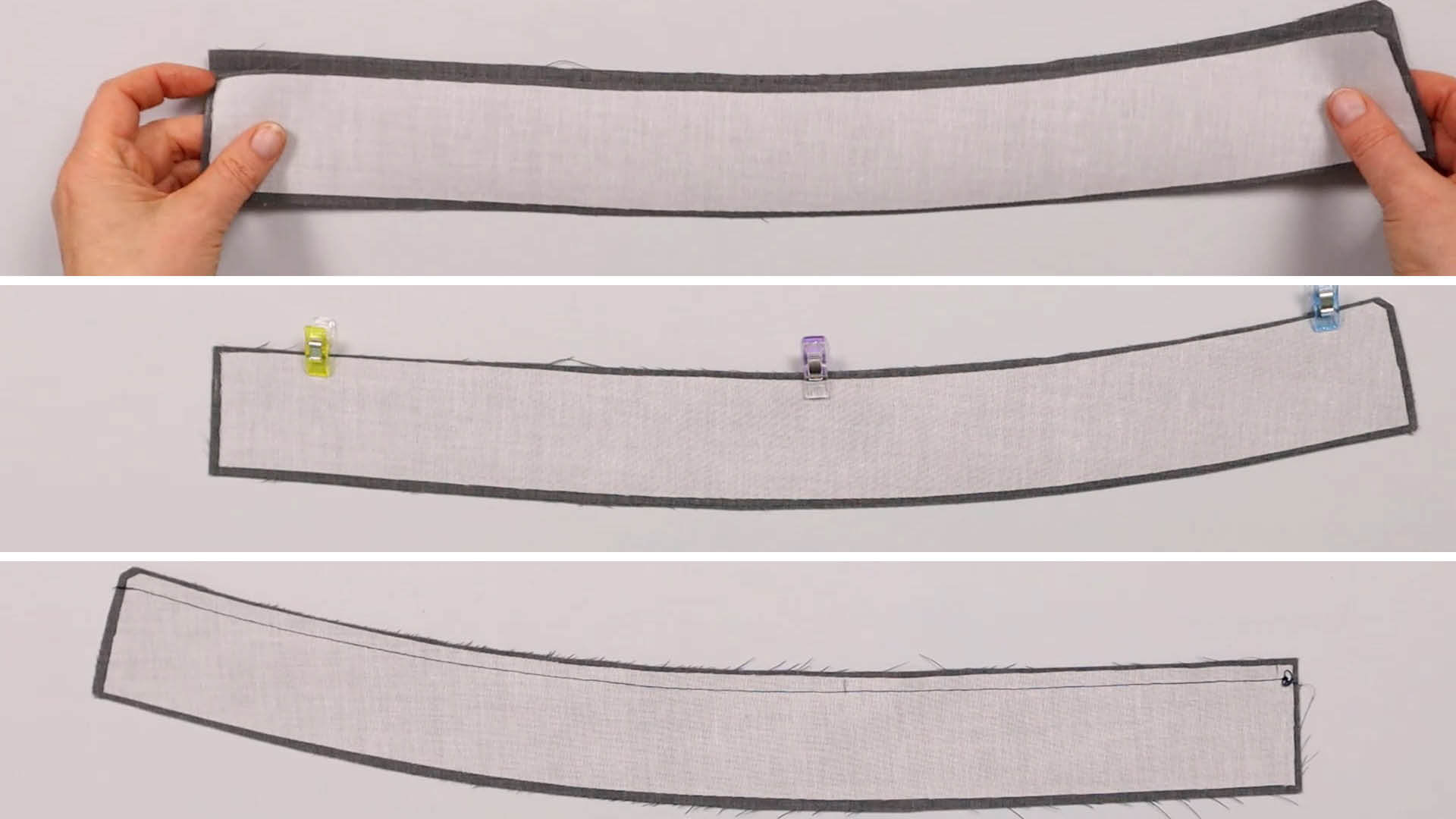

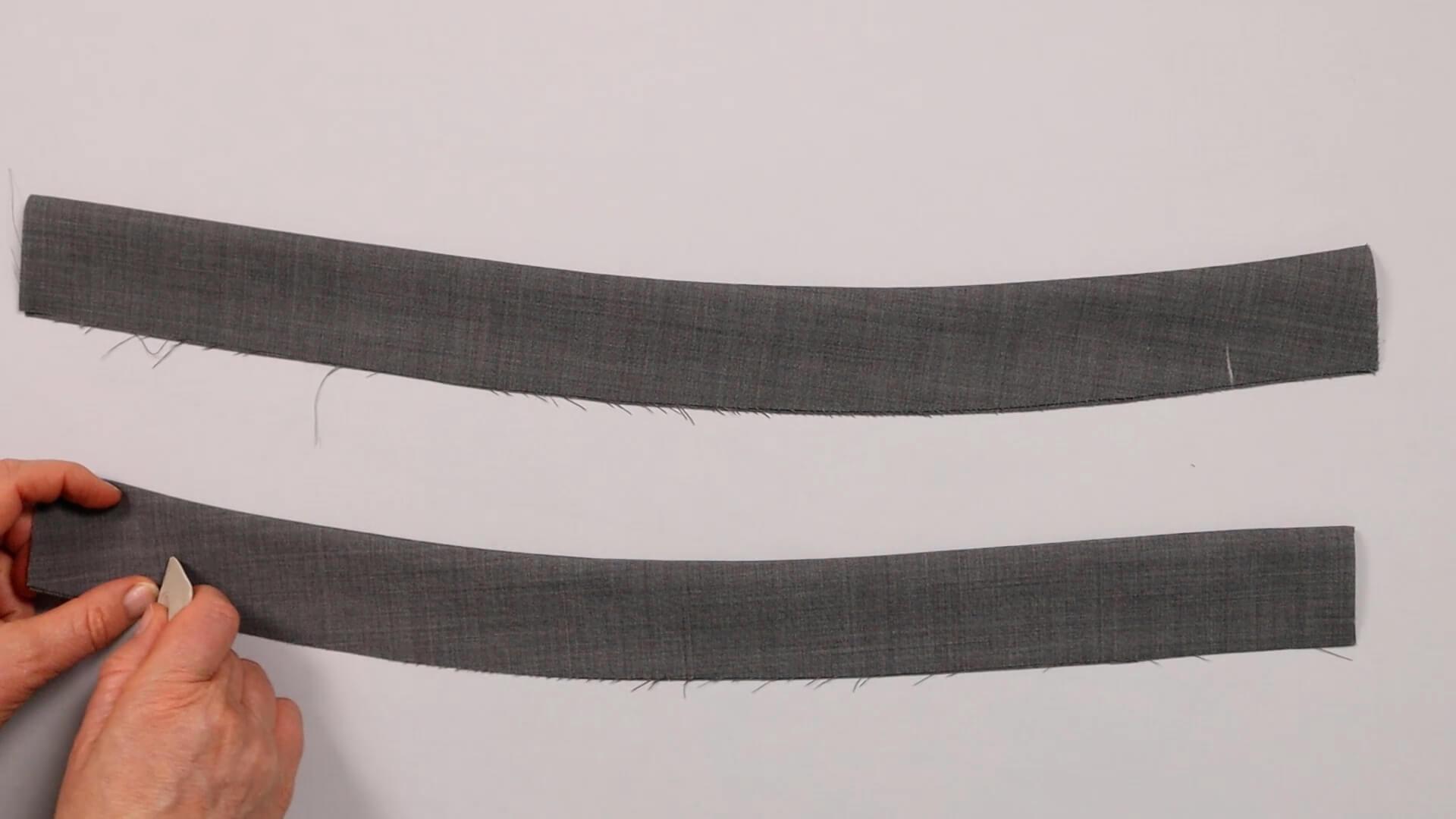

If you haven’t done this yet, iron the interfacing onto the waistband. You will have a total of four waistband pieces onto which you can iron the interfacing – depending on the fabric and the desired stand of the waistband- either on the outer waistband pieces only or on all pieces. If you only want to reinforce the outside, make sure that you iron the interfacing onto the right parts.

Prepare the right and left waistband stripes separately. To do this, I lay the two pieces right sides together, pin them at the top edge and sew them together using a normal stitch length. The beveled corners on the identify the top of the pattern pieces.

With a shaped waistband, I cut the seam allowance at the top edge of the waistband several times to release the tension when turning the waistband right side out. To minimize the visibility of the incisions, I offset the incisions at the top and bottom.

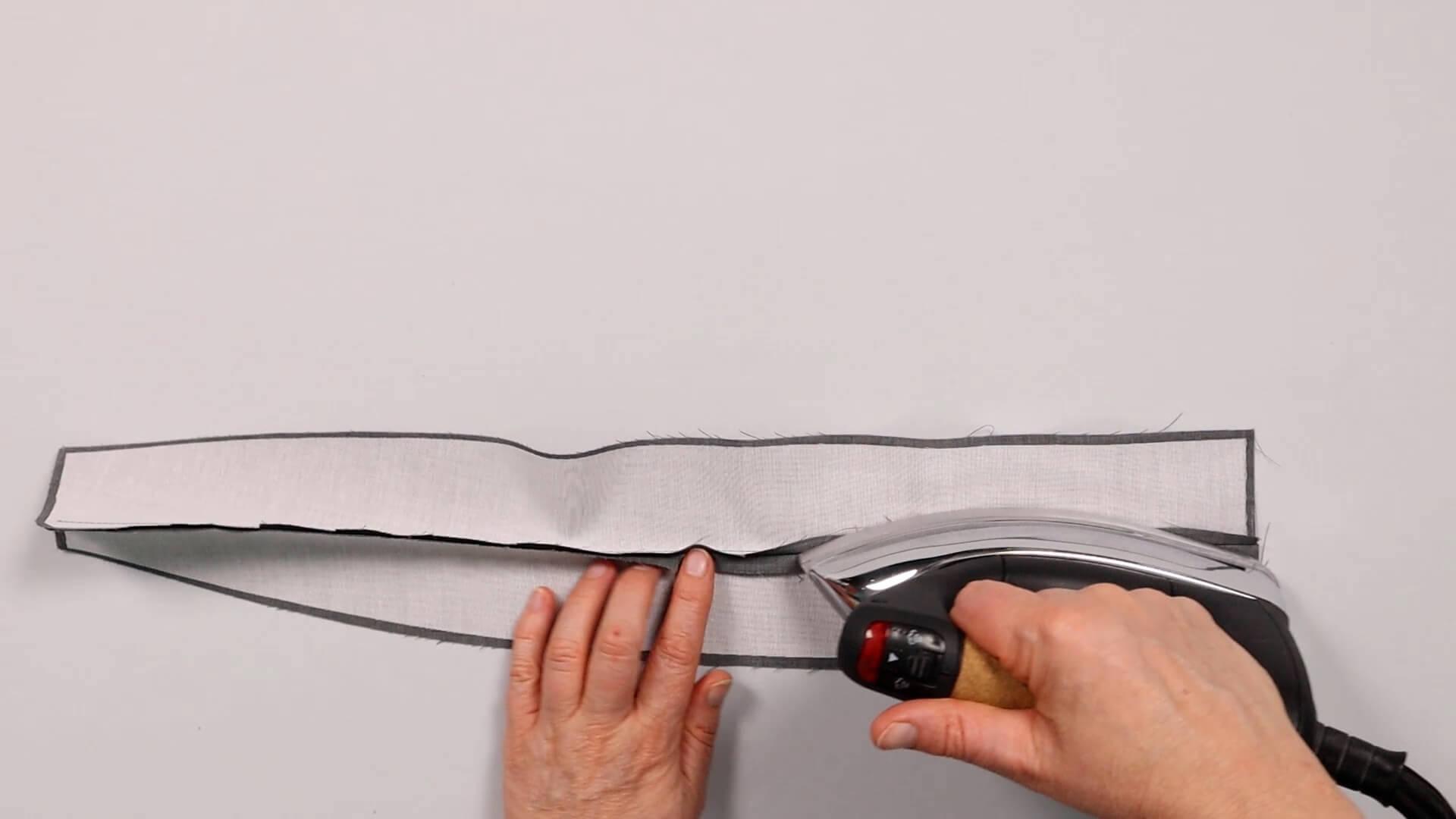

Then I press the seam allowance open.

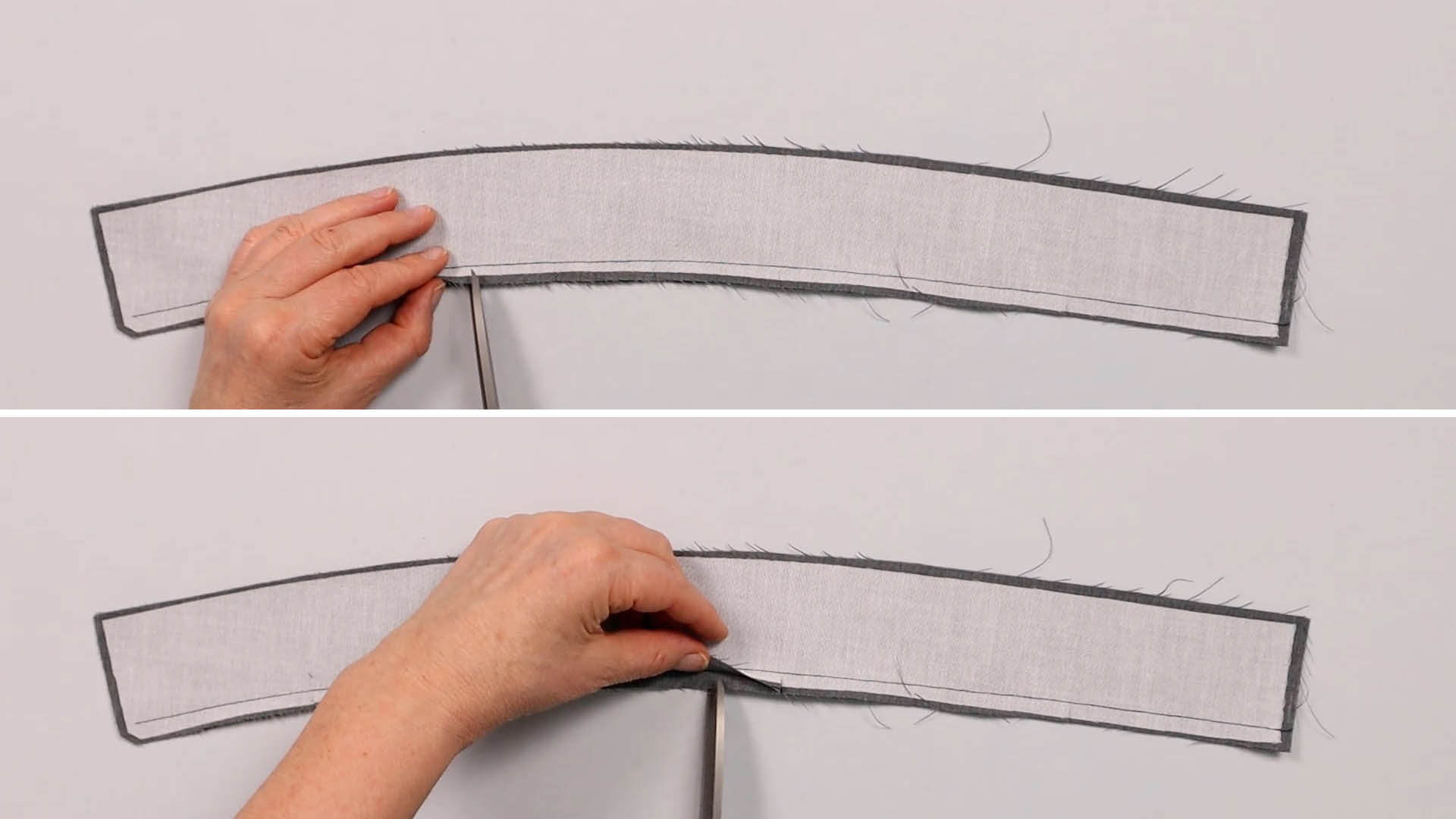

I then lay the waistband with the wrong sides together and press the seam slightly towards the inside of the waistband so it is not visible from the outside later on.

I place the brush on the pressed seam so that it cools down more quickly. The (unpainted) wood absorbs the moisture, making the seam crisp. If you have a tailor’s clapper, you can of course use that too.

When cutting, I transferred the notches from the pattern pieces by making small incisions within the seam allowance. I mark these with tailor’s chalk. When shaping the waistband, make sure you do not mix up the center front and center back of the waistband strips.

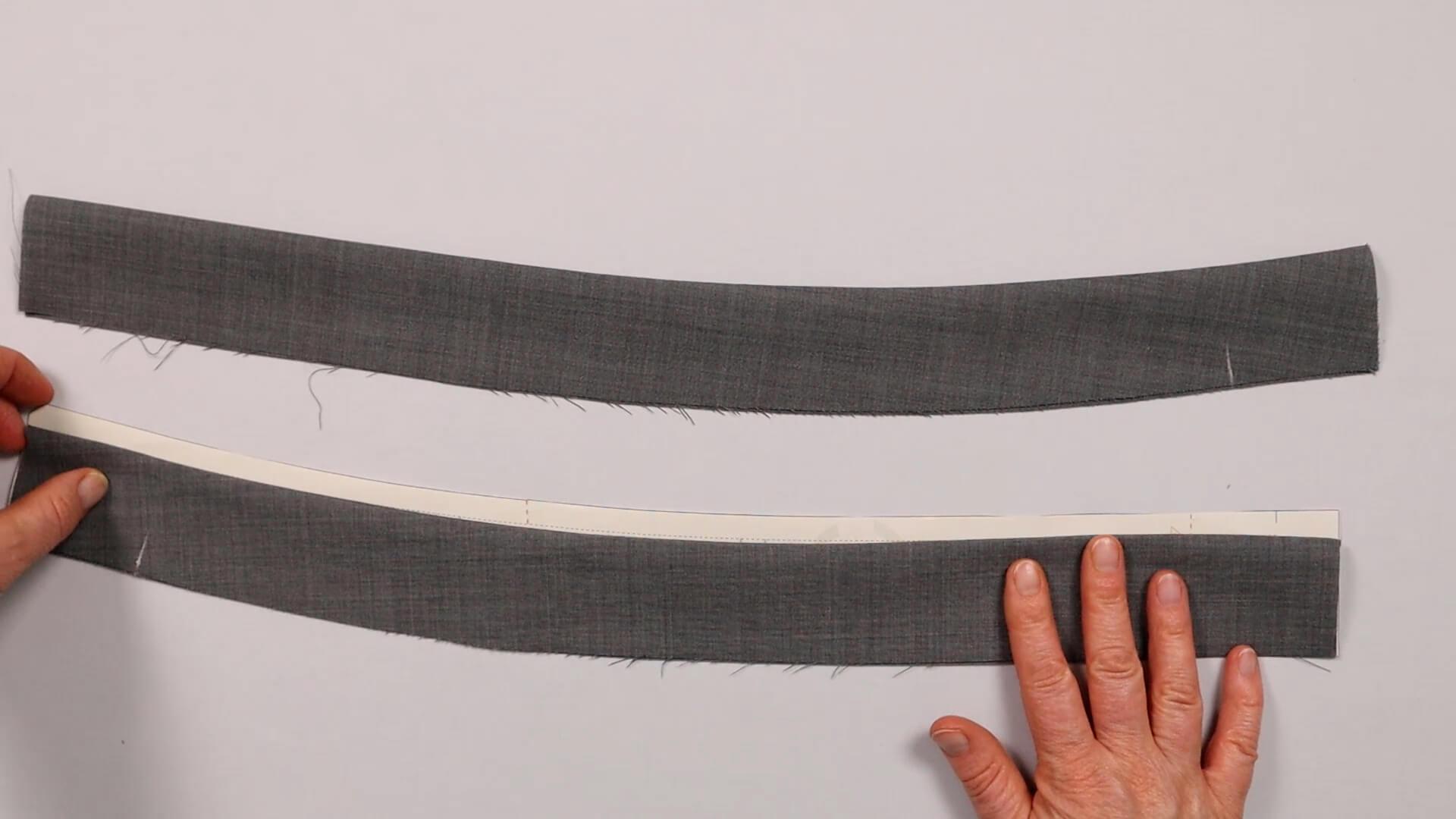

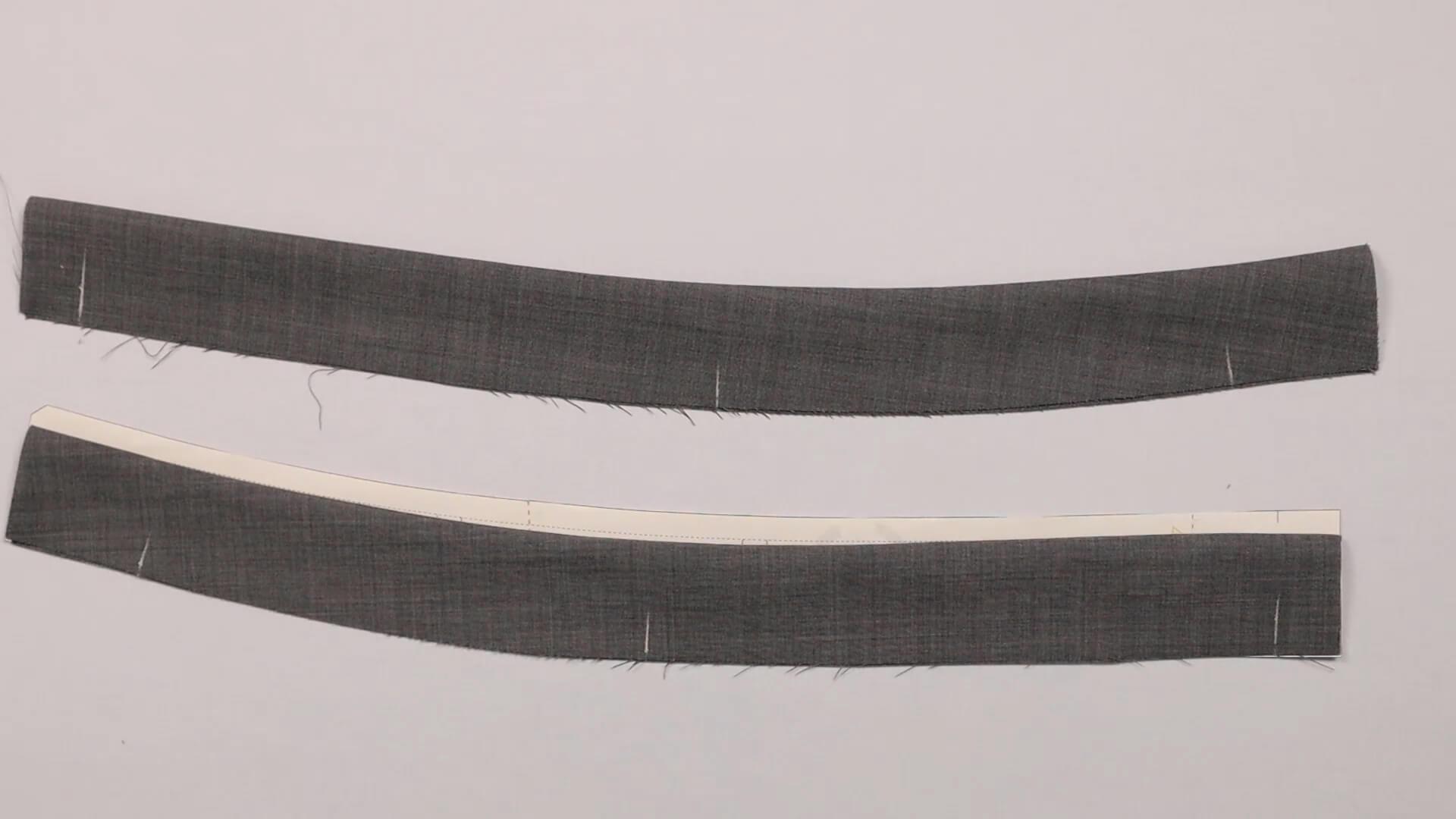

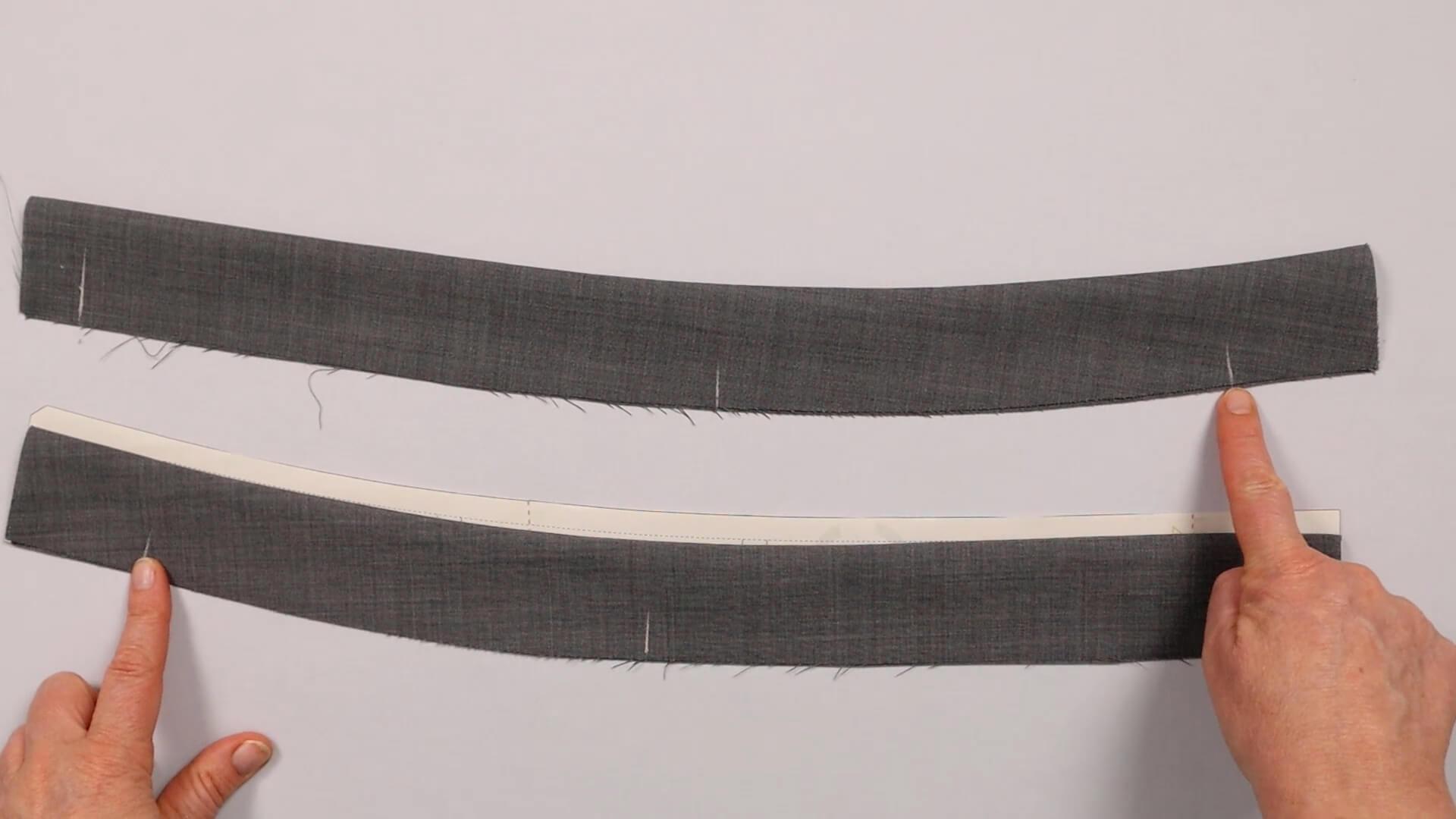

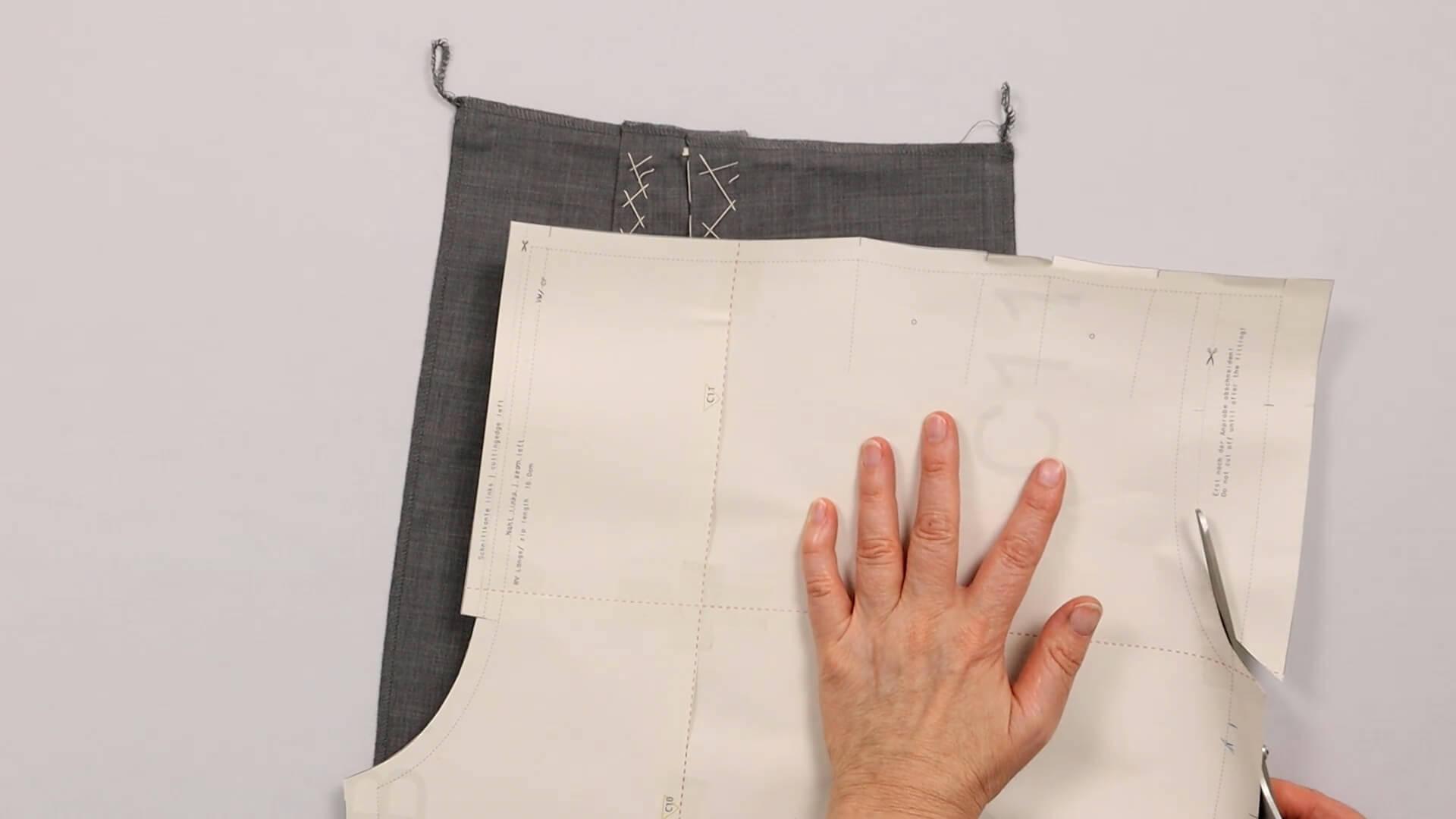

Use the paper pattern piece to check if the waistband lengh is still correct. If the lenght has changed, make sure to take this into account while transferring the notches.

Then I also mark the notches for the side seam and center back.

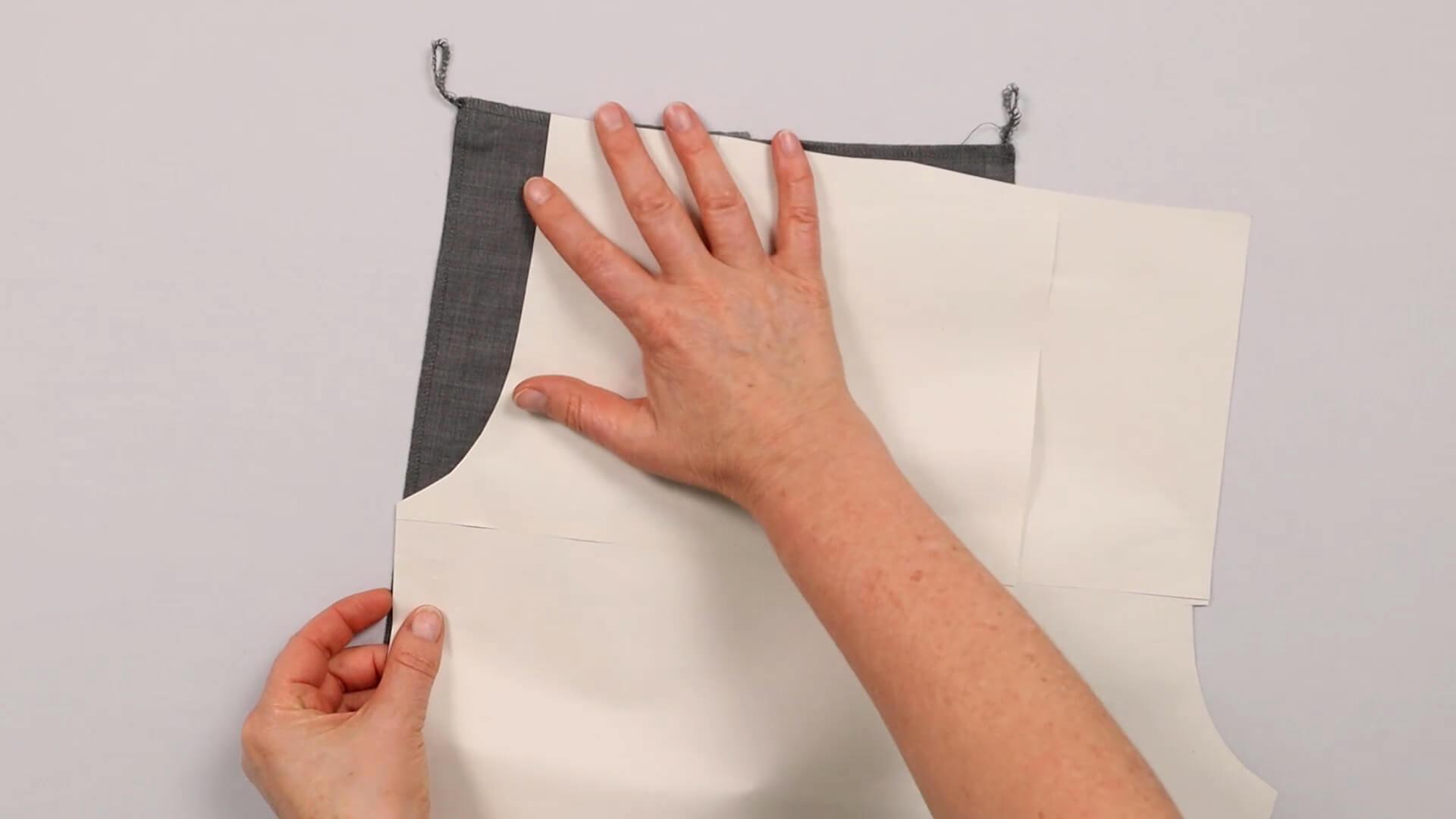

The waistband parts must be mirrored. The image shows the fingers are placed on th centre front of the waistband.

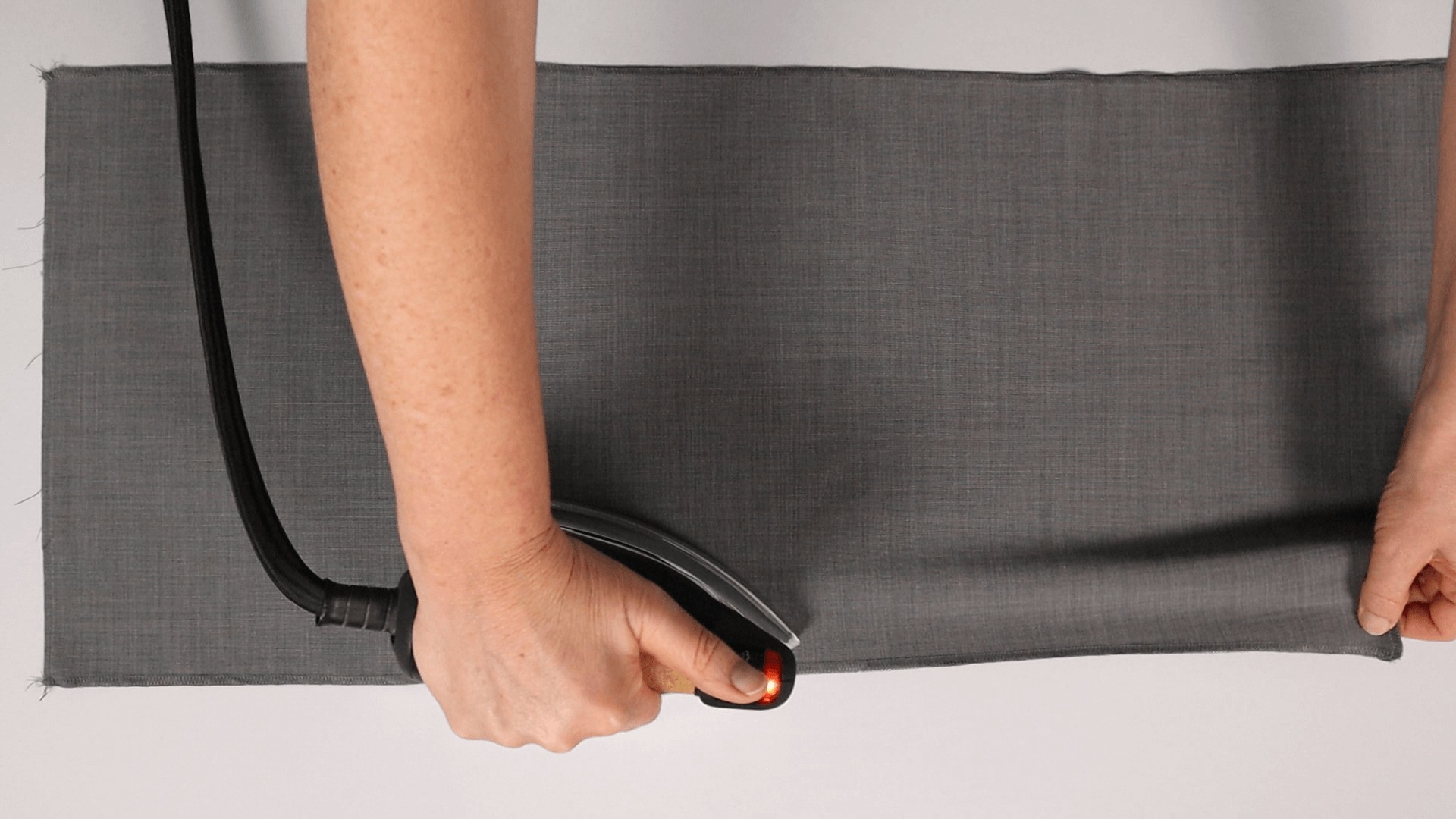

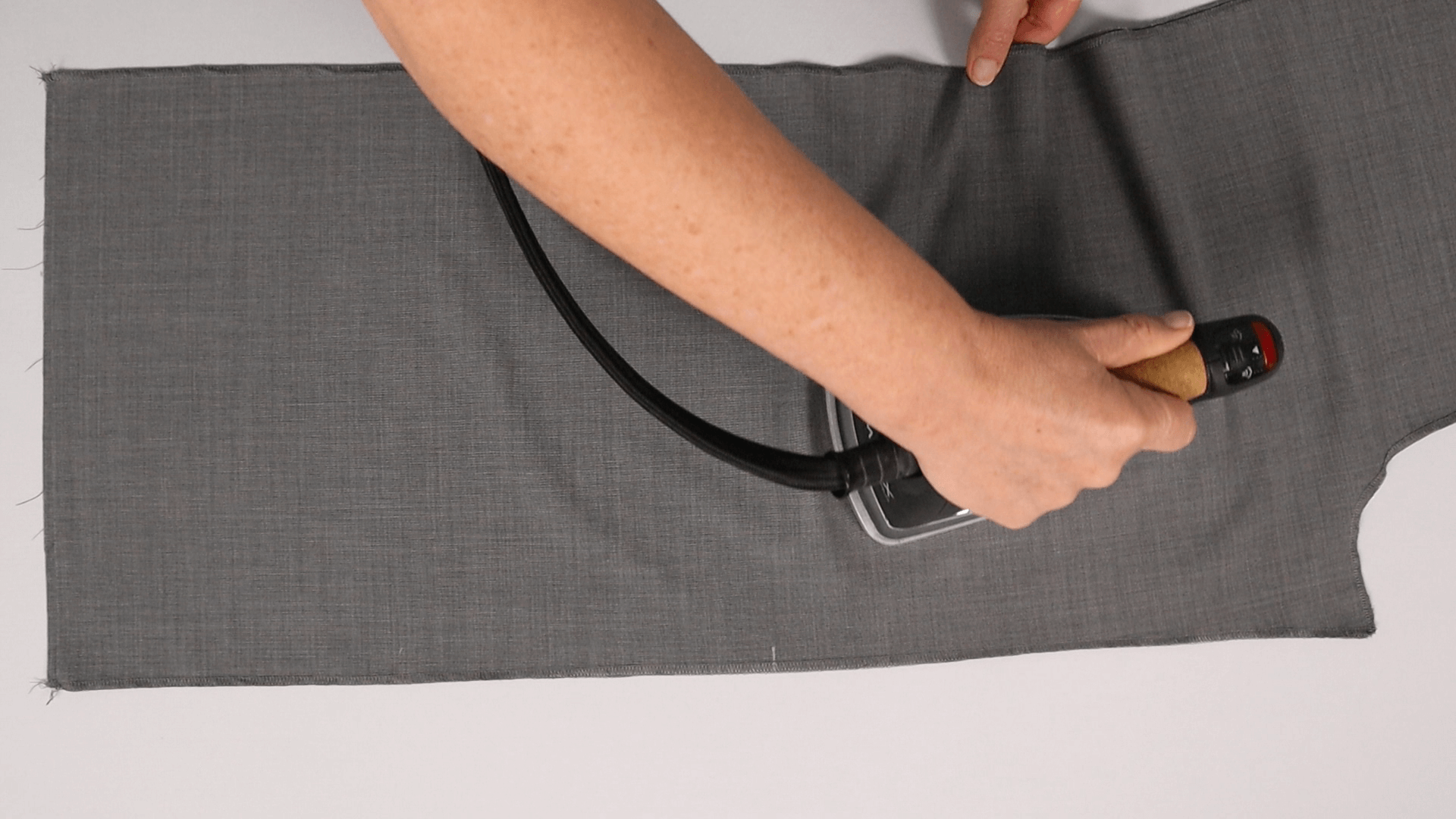

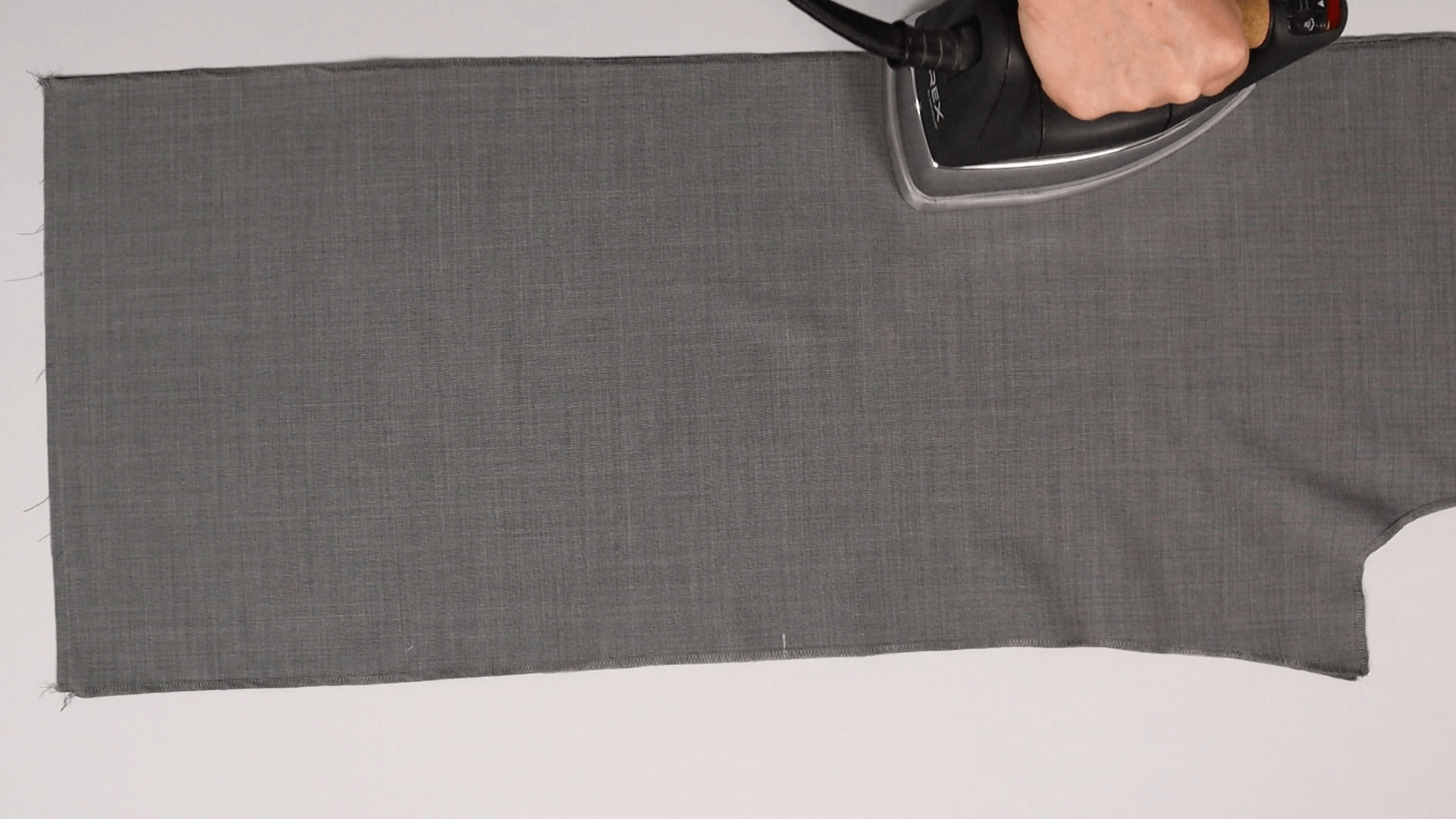

3. Iron the back of the trousers into shape

First I iron the back trousers into shape. In this example the edges have been finished with an overlock seam. It is up to you if you want to do it now or later when the leg seams are closed. This will be explained later again.

Place the back pieces right sides together and mark the notches around the knee area.

Starting at the notch previously marked I iron upwards, stretching the inside seam by around 10mm.

I try to iron the width slightly towards the middle of the leg below the bottom, this is the area where most fabric will be accumulated. This technique works best with woolen fabrics.

Repeat this a few times.

Then I lay the trousers straight again in the grain and iron them smooth from the side seam.

I then turn the pieces over and iron the other side in the same way.

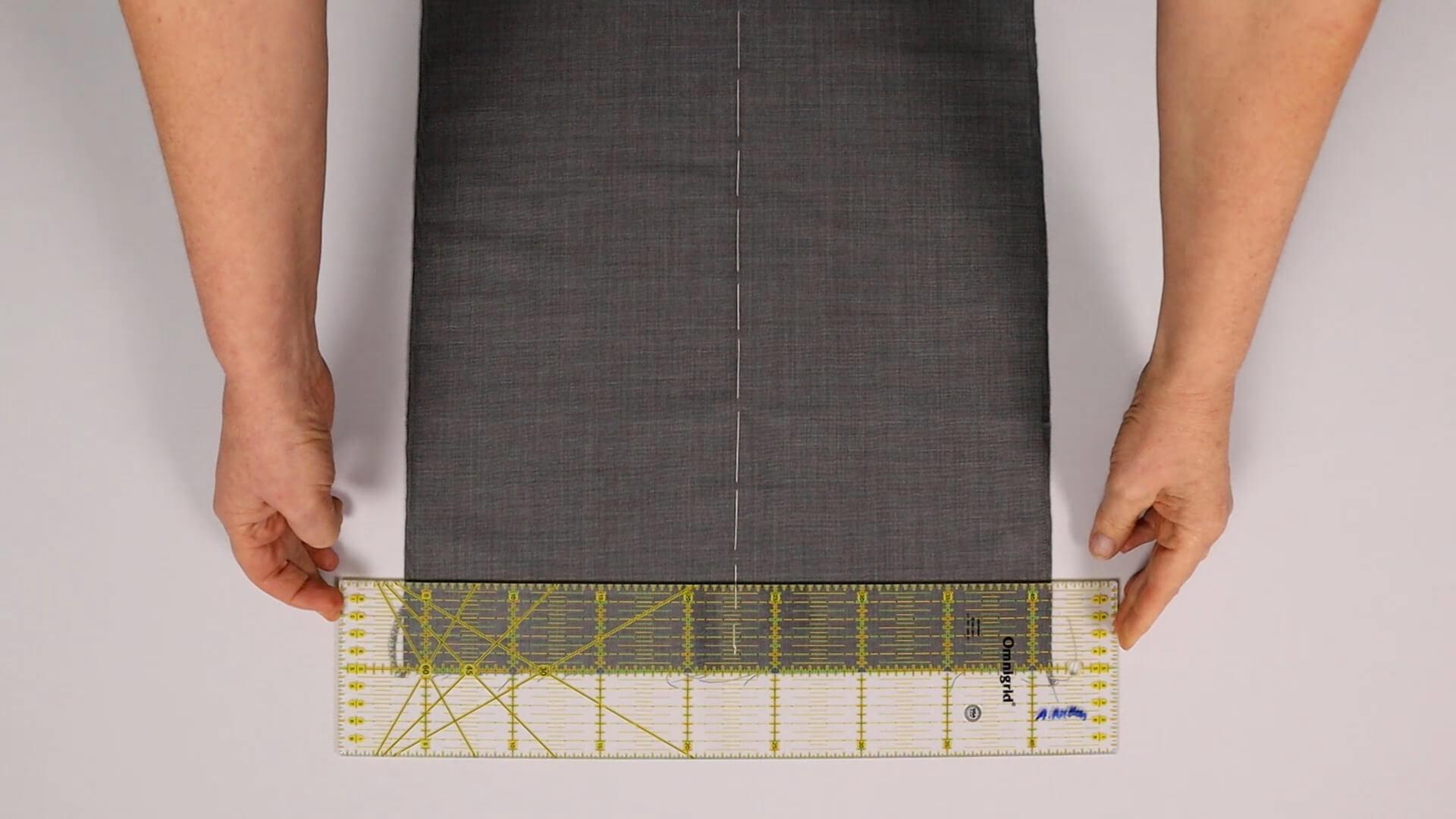

4. Prepare the hem for fitting

If you have opted for a normal turned-in hem, mark the hem length specified in the pattern on the right side of the fabric parallel to the hem edge. To try on the trousers for fitting, the hem is folded inwards at this line and pinned in place.

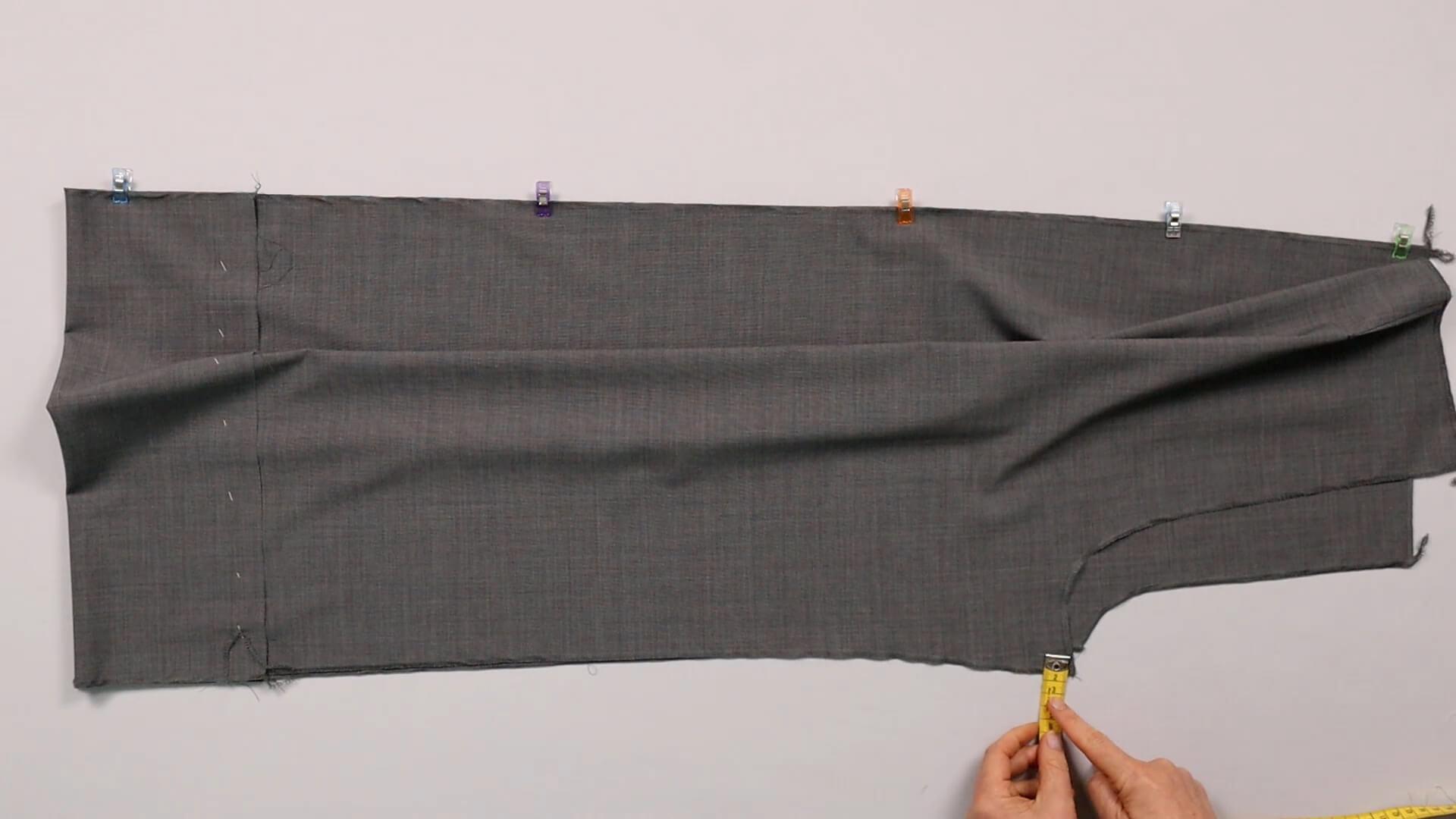

With a hem turn-up, the part that is folded inwards is very wide. The processing therefore differs from that of a normal hem. I place the template for the turnup hem (P-H) neatly aligned with the cutting edge.

Then I transfer the marking for the inner hem edge onto the right side of the fabric.

For the other side, I turn the template over and mark the inner hem edge too.

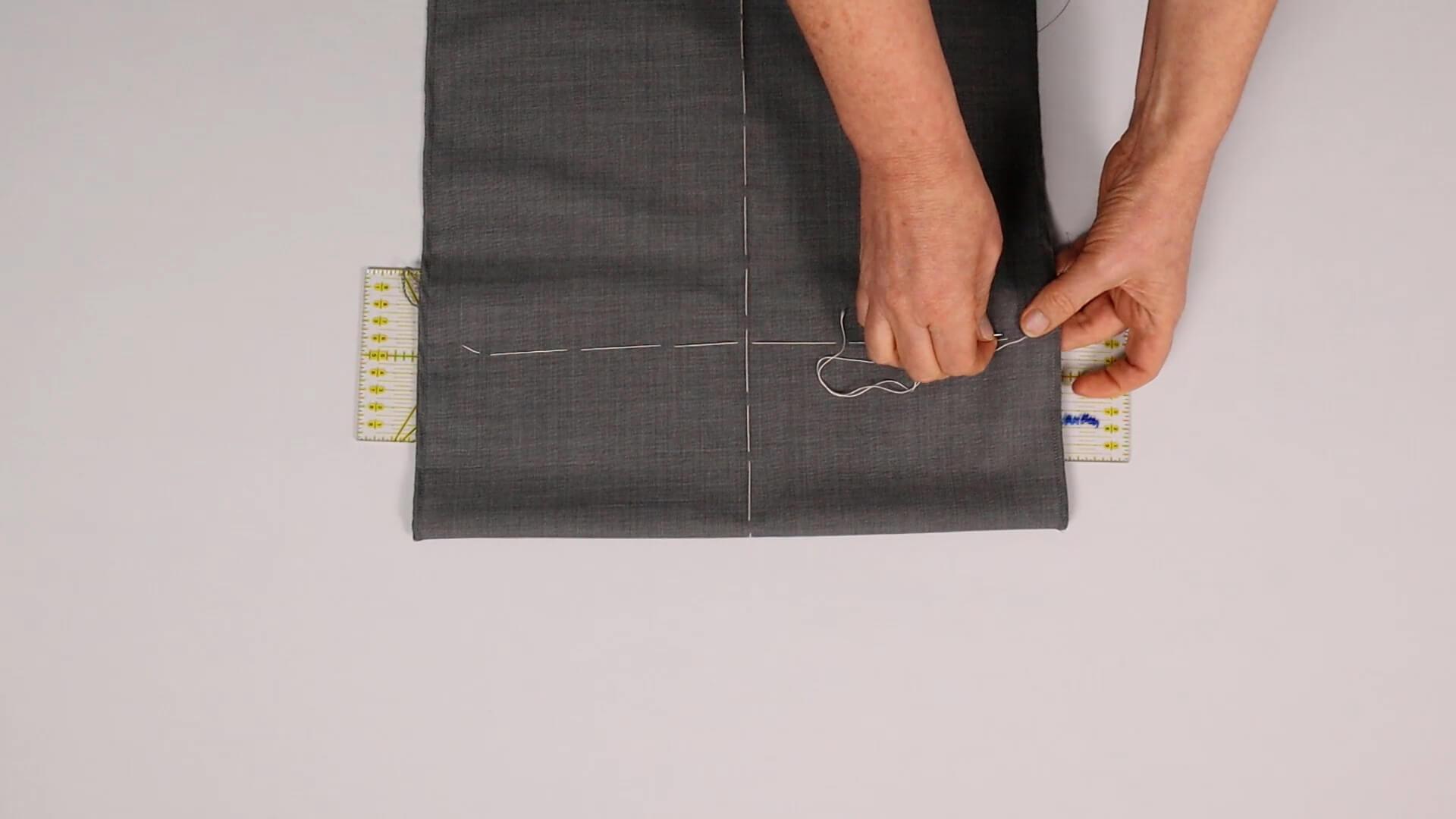

I secure the hem with a few long stitches. I put the ruler under the basting seam to avoid stitchin through the ironing board.

I repeat these steps – marking, folding over, basting – with the other three pattern pieces of the front and back trousers.

5. Close the leg seams

Now I close the inner and outer leg seams. To do this, I place the front trousers right sides facing up. Then place the back trousers right sides together on the front trousers.

The outer leg edges are pinned together neatly.

Pay attention to the notches at knee hight and possibly in the pocket area.

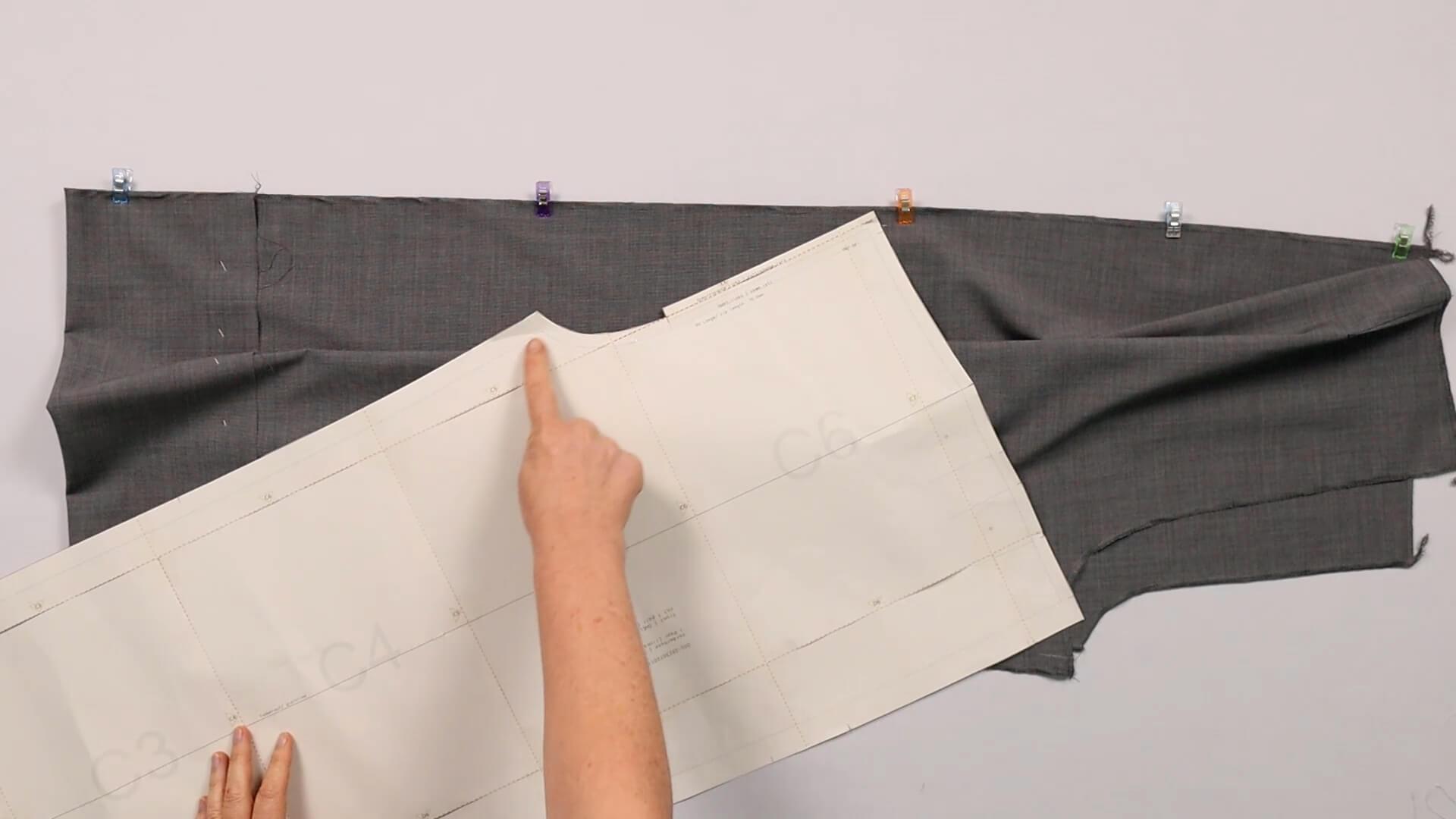

You can see from the pattern piece how wide the seam allowances are.

At the upper end of the inside leg seam, I mark the seam allowance on the back trousers.

In this position, I secure the upper end of the inner leg seam with a clip or pin. The front and back trousers meet exactly at the marking in the crotch curve.

Then I pin the remaining section of the inner leg seam together and make sure that the notches meet at knee hight.

I baste both seams with a straight stitch with a long stitch length or by hand. Make sure to sew with the seam allowances indicated in the pattern.

6. Mark the pocket position on the back of the trousers

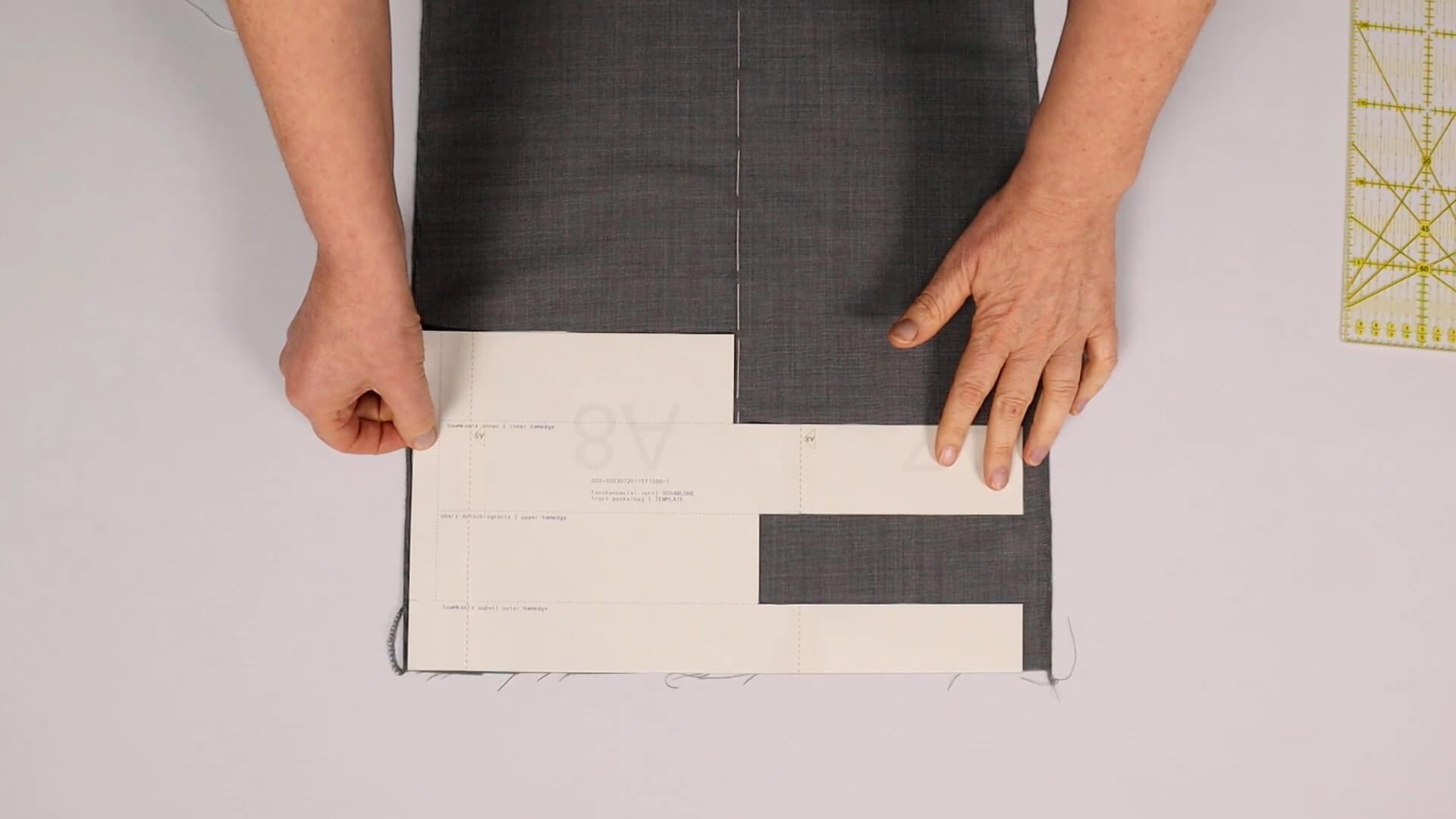

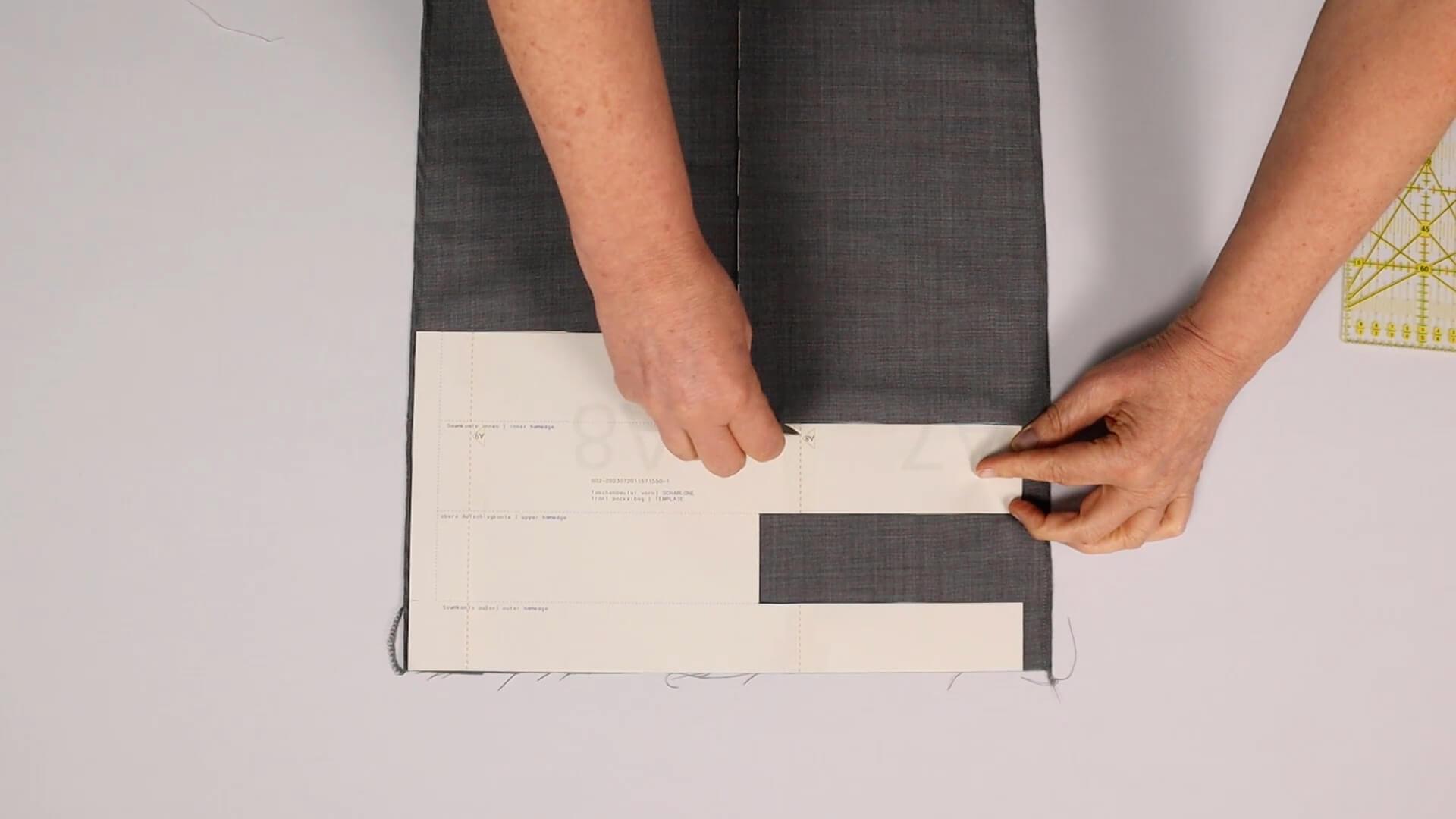

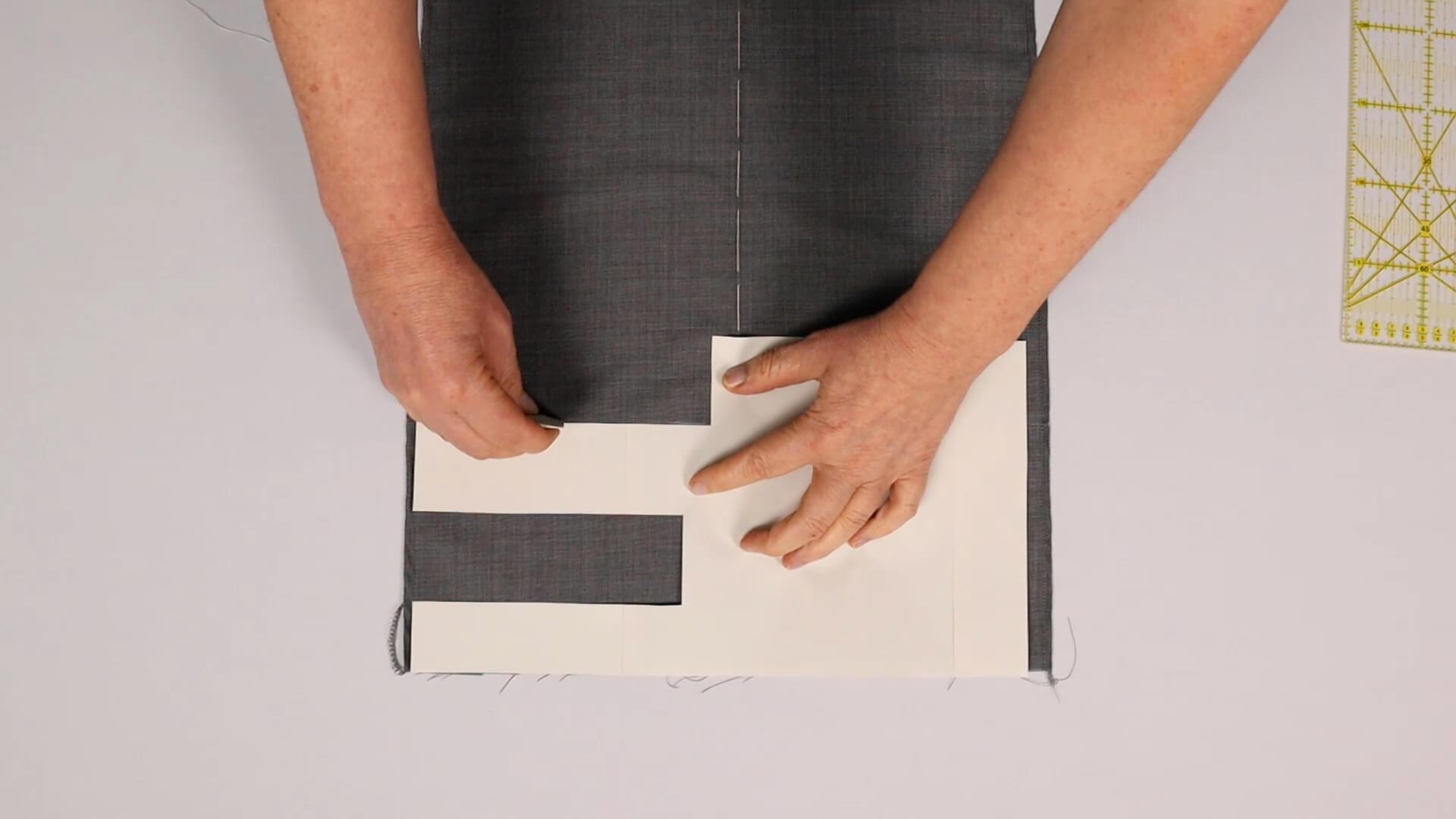

There is also a template for the position of the back pocket. Here you can see the template for welt pockets. The procedure is identical for all pocket variations.

I align the template with the center back and the top edge of the back trousers.

Then I mark the pocket position with tailor’s chalk.

Marking the position of the pockets will give you an idea where they’ll sit later. If you don’t like the position, you can still make changes.

7. Pin the waistband stripes to the trouser legs for fitting

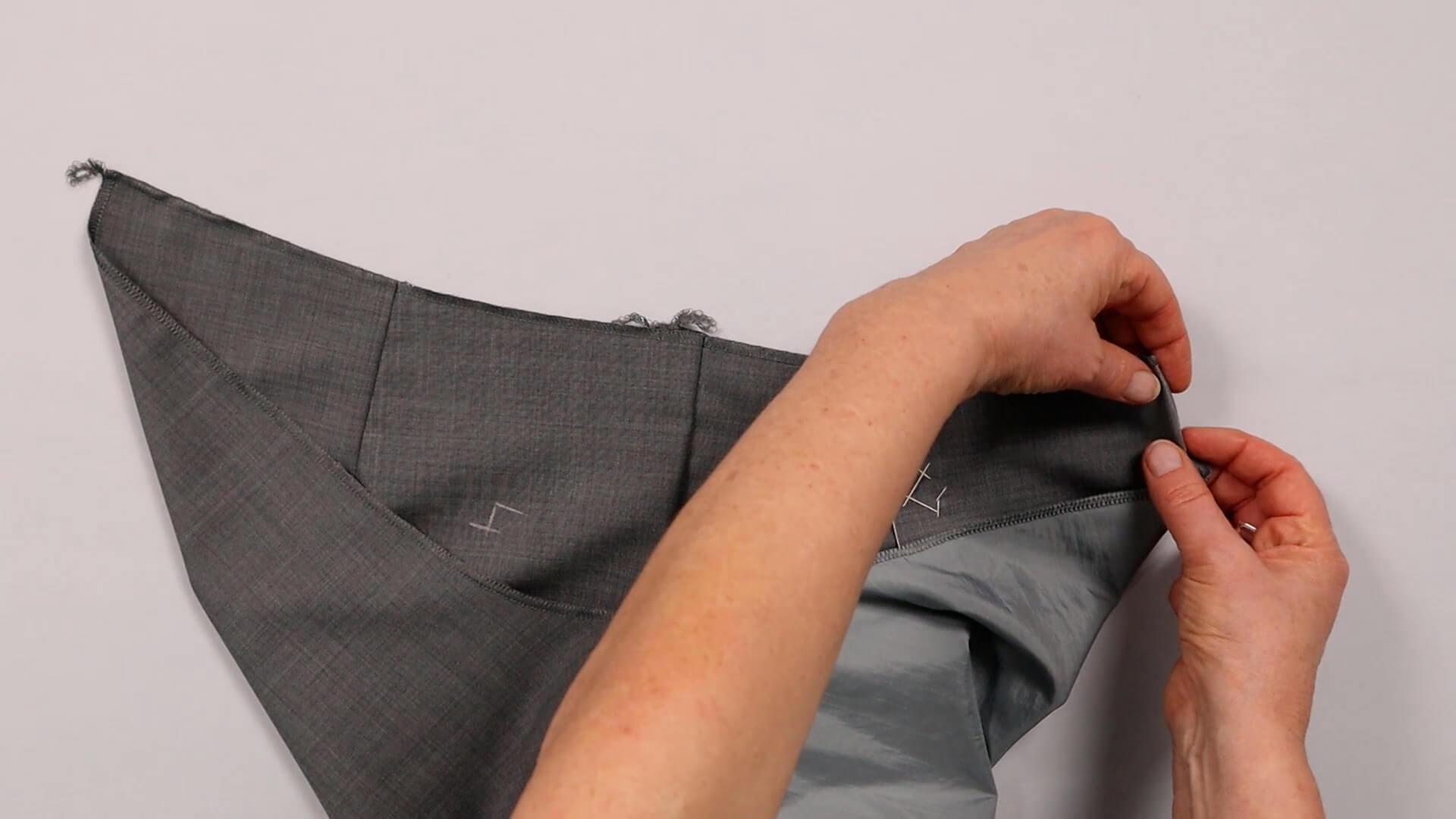

Before I pin the waistband stripes to the trouser legs, I transfer the marking for the center front. Since my trousers have a knee lining, the edge has already been finished with an overlock stitch.

I place the trousers in front of me, as shown in the picture.

At the center front just marked, I turn the crotch seam on the overlap side, in this case on the right front piece, to the inside.

I place the waistband strip with the marking for the center front on the folded edge.

The notch in the middle of the waistband meets the side seam exactly.

The waistband strip and back trousers also meet exactly at the center back.

I start by pinning the waistband strip to the trousers at the center front.

Then I continue all the way, aligning all notches. To try on the trousers for fitting, the waistband can be basted double layer with a long stitch length or by hand.

I repeat the steps for the second trouser leg. This time the fly is not folded over.

In the picture you can see the prepared left trousers.

8. Basting the crotch and seat seam

I mark the width of the seam allowance in the center back on the wrong side of the right trouser leg. You can tell the exact width by the notch at the waist edge. You can also measure in the pattern piece.

I mark the notch on the lower crotch curve. From there all the way to the front, the seam allowance is 10 mm.

The center back seam is defined joining the two markings on the back trousers.

Then the two trouser pieces must be placed right sides together.

To do this, first turn the left trouser leg right side out.

I then slide the turned trouser leg into the right leg on which I have marked the seam line.

I align the crotch seam of both leg pieces.

Make sure all notches meet as well as centre front and side seams. Pin everything in place before sewing.

I mark the end of the crotch seam, right below the fly. This will also be the end of the basting stitch.

This is what the joined trouser pieces look like from the left side.

9. Final preparations before fitting

Now you can turn the trousers right side out and get a first impression of how they will look later.

I fold the seam allowance of the upper edge inwards and baste with a few large stitches.

I mark the centre front on the side with the fly shield and do so along the entire length of the fly.

The folded edge hits this mark exactly. When you try on the trousers, make sure the center front of the waistband is exactly on top of each other. It is best to pin it in place with a safety pin.

10. Fitting

Now the time has come – you can try on your trousers for the first time!

Here are a few tips on what to look out for when trying them on:

- To get an impression of how the trousers fit, I recommend taking photos including at least the three perspectives in the picture above. You should take the photos as straight as possible – i.e. not at an angle from above or below.

- Make sure the waistband is at the right hight. As there is still no button to close the trousers properly, they can easily be pulled up a little too high or too low. To check this, you measure the side length from the floor to the top edge of the waistband (see marking) and compare it with the side length you entered in the configurator.

- If the waistband sits at the right hight but is still too tight or too wide, compare the measurement you entered when configuring with the circumference measurement at the point where your waistband sits now.

- If the trousers seem a little too wide at the hips, remember that pockets are still being worked in. Depending on the thickness of the fabric, they also need a little space. It is best to try the trousers on again briefly before sewing the waistband on the inside.

- The tighter the fit you have chosen and the less stretchy your fabric is, the more likely it is that the trousers will wrinkle at the back of the legs. This is because the trousers have an extra length at the back, which you need to sit down comfortably.

- Wrinkles sometimes look worse in photos than they actually are. Be sure to take another look in the mirror to see what it really looks like.

If you still have problems with the fit, please send me an e-mail with pictures of how the trousers look when worn (see above). I will then try to help you with the adjustments. This works much better at this point than at a later date.

11. Transfer changes and undo seams

When you have finished fitting the trousers and have made all adjustments to the pattern, all seams can be unpicked. Please note: the basting seams of the waistband and creases are not removed.

If you have chosen closed pleats, you will find the next steps for stitching them closed at point 5 of these instructions.

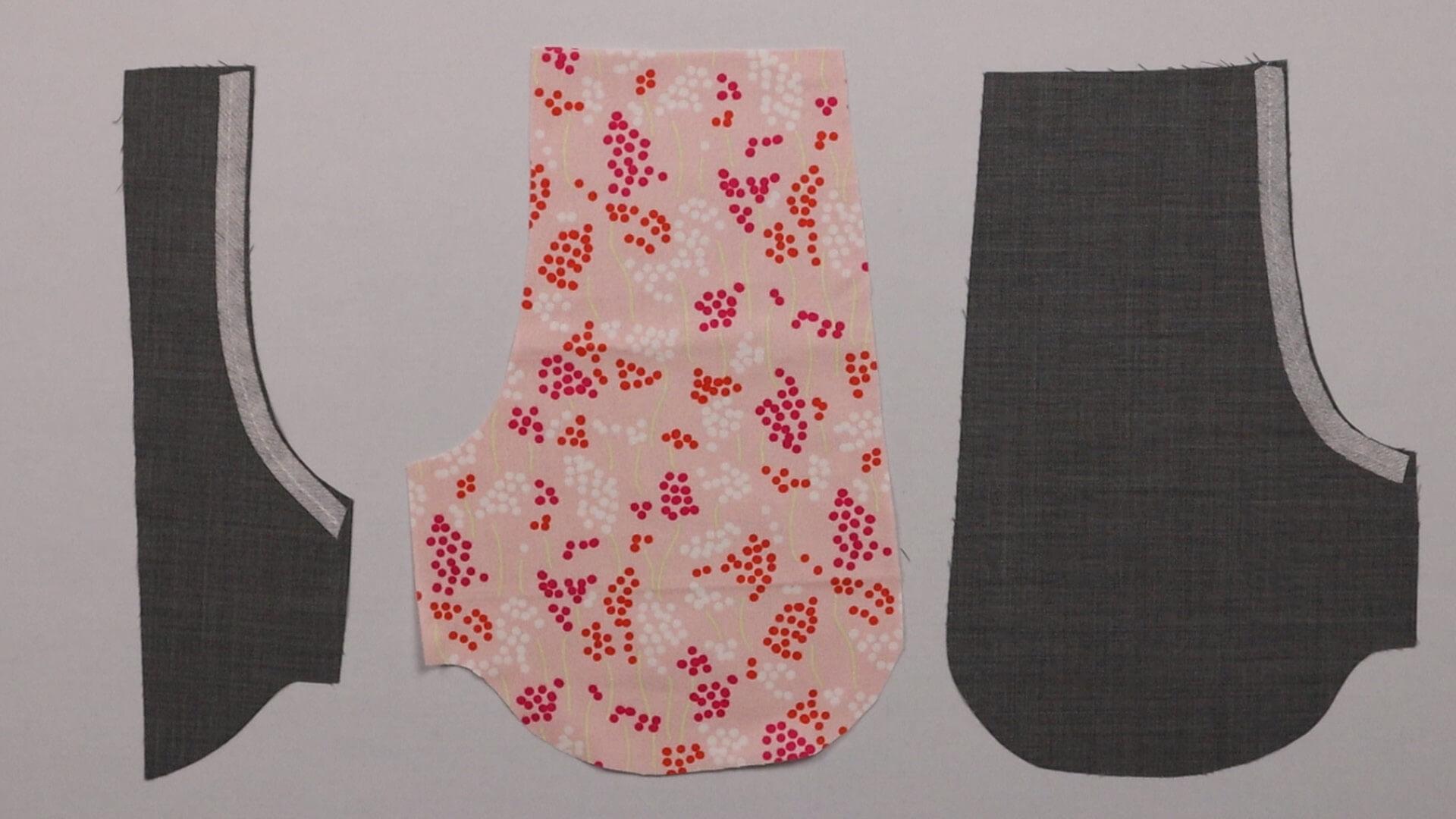

12. Cut the pocket opening of the front trousers to size

If the trousers have french (not welt or inseam) pockets, these must now be cut to size.

First, I cut away the pocket opening on the paper pattern according to the marking.

Then I place the pattern piece on the front trousers and mark the pocket opening on the right side of the fabric.

If you have unlined front trousers, you can cut away the pocket opening. Repeat the steps for the second front trousers before continuing with the next step (see links below).

On the lined front trousers, I secure the pocket opening before cutting off the excess fabric.

To do this, I sew through both layers of fabric just next to the marking. I can then cut away the pocket opening at the marking. I repeat these steps for the second front trousers.

In the case of lined trousers with slit pockets, reinforcing the slit on the lining of the front trousers would not work well. Therefore, the pocket opening is reinforced on the facing of the upper pocket bag on the left side of the fabric, as shown in the picture on the left.

If you sew the upper pocket bag without a facing, the pocket bag itself will be reinforced (right picture).

Here you will find the links to the next step. Select the link that belongs to the bag shape you have chosen.

- Sew patch pocket on trousers #TH01

- Sew double welt pockets into trousers #TH02

- Sew welt pockets into trousers #TH03

If you don’t want pockets on the back trousers, continue here:

If you’re not quite ready yet and perhaps want to start at the beginning, you’ll find some links here: